Soo bandhigid kooban ee electrode graphite

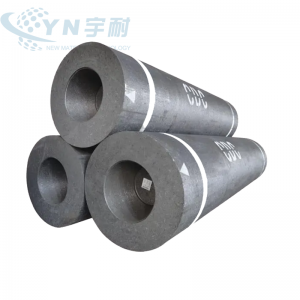

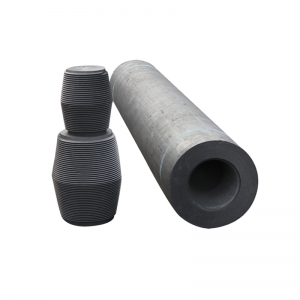

Graphite electrode waxa loola jeedaa coke batroolka, coke garoonka sida wadar ahaan, garoonka daamurka dhuxusha sida binder, waana nooc ka mid ah electrode adkaysi u samayn by calcination of alaabta ceeriin, burburin iyo shiidi, dubista, cajiin, qaabaynta, dubay, impregnation, graphitization iyo farsamada makiinado.Qalabka garaafyada heer-kulka sare leh waxaa loo yaqaannaa elektrode graphite artificial (oo loo yaqaan 'graphite electrode)

Kala soocidda graphite electrode

(1) Electrodes garaafyada awoodda caadiga ah.Waa la ogol yahay in la isticmaalo electrodes graphite leh cufnaanta hadda ka hooseeya 17A/cm2, kuwaas oo inta badan loo isticmaalo foornooyinka korontada caadiga ah ee samaynta birta, dhalada silicon, dhalada fosfooraska jaalaha ah, iwm.

(2) Ka-hortagga oksaydhaynta dahaarka leh ee garaafyada.Electrode-ka graphite ee lagu dahaadhay lakabka ilaalinta oksaydhaynta waxay samaysaa lakab difaac kaas oo labadaba maamula oo adkaysi u leh oksaydhka heerkulka sare, yaraynta isticmaalka korantada inta lagu jiro samaynta birta.

(3) Electrodes graphite awood sare leh.Electrodes graphite leh cufnaanta hadda ee 18-25A/cm2 waa la ogol yahay, waxaana inta badan loo isticmaalaa foornooyinka korantada ee awoodda sare leh ee samaynta birta.

(4) Electrodes garaafyada awoodda aadka u sarreeya.Electrodes graphite leh cufnaanta hadda ka weyn 25A/cm2 waa la ogol yahay.Inta badan loo isticmaalo birta samaynta tamarta aadka u saraysa ee foornada korantada

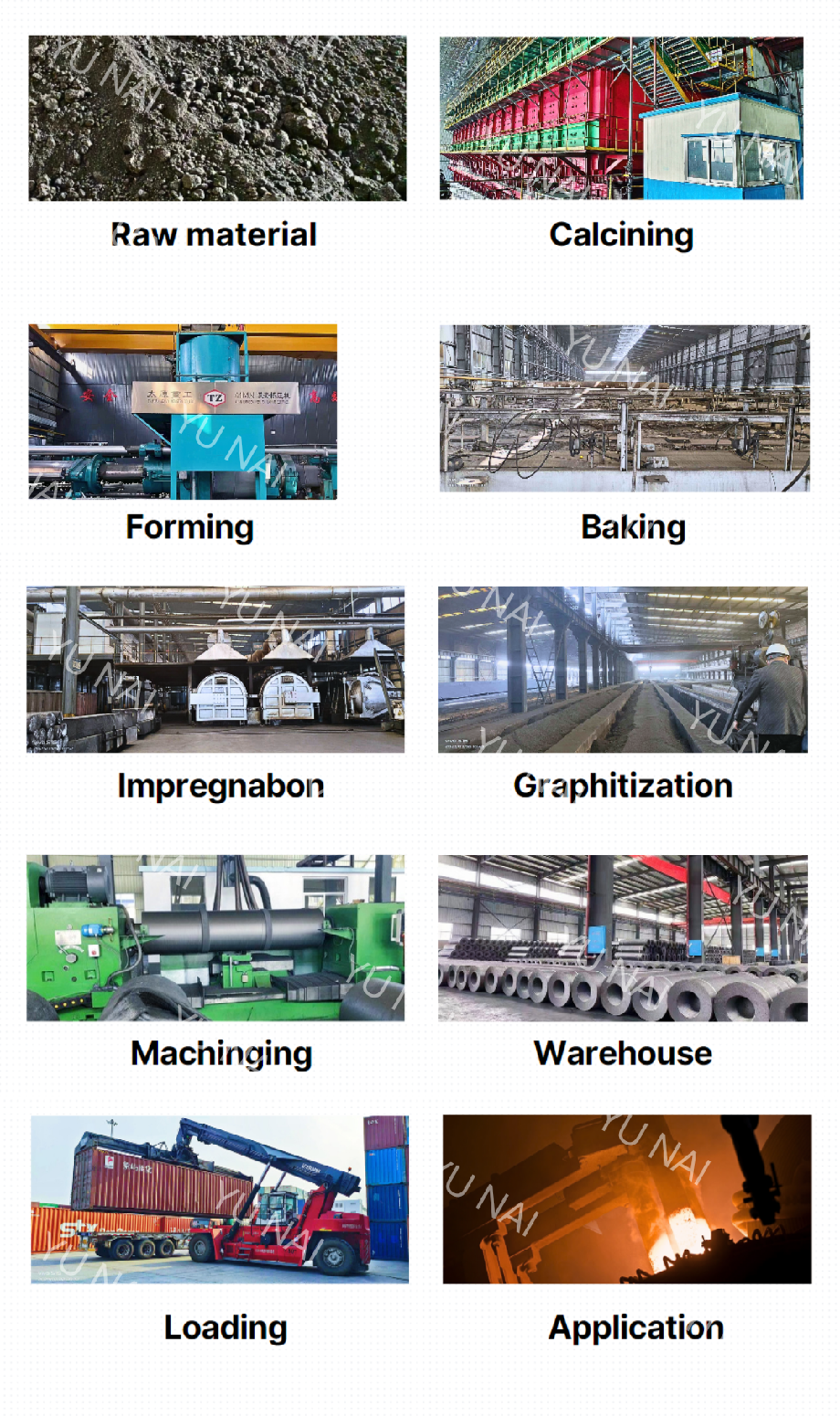

Habka wax soo saarka ee electrode graphite

Tilmaamaha korantada graphite

1. Korantada sare iyo kuleylka kuleylka;

2. Iska caabbinta gariirka kulaylka sare iyo xasilloonida kiimikada;

3. Dufan wanaagsan oo waara;

4, fududahay in la farsameeyo, saarista biraha sare iyo khasaaraha graphite hooseeya inta lagu jiro EDM (dhimbiil koronto)

5. Miisaanka gaarka ah ee garaafka waa 1/5 oo naxaas ah, garaafka wuxuu miisaankiisu yahay 1/5 miisaanka naxaasta oo isku mid ah.Electrode-ka weyn ee ka samaysan naxaasta ayaa ah mid aad u culus, taas oo u xun saxnaanta mashiinka EDM ee qalabka casriga ah inta lagu jiro dhimbiil koronto oo dheer.Taas lidkeeda, graphite aad bay ammaan u tahay in la qabto.

6, Graphite waxay leedahay xawaare processing sare oo 3-5 jeer ka dhakhso badan biraha caadiga ah.Waxaa intaa dheer, doorashada qalab-engegan ku habboon iyo graphite waxay yarayn kartaa xijaabka iyo ilmada gooya iyo electrode.

Ka taxadar isticmaalka graphite electrode

1.Marka la isticmaalayo ama lagu kaydinayo electrode ah, isticmaalayaashu waa inay hubiyaan inay iska ilaaliyaan boodhka qoyaanka, wasakhowga

iyo isku dhacyada.

2.Marka electrodes ay qaadaan baabuurta forklift, dheelitirkooda waa in la ilaaliyo si looga hortago

siibasho iyo jabid.Isku dhaca iyo culeyska xad dhaafka ah waa mamnuuc.

3. Electrodes waa in lagu kaydiyaa meelo nadiif ah oo qalalan.Marka lagu kaydiyo kaydka hawada furan

waa in lagu daboolaa taarpaulins.

4.Marka la isku xidho electrodes, dadka isticmaala fifirst waxay u baahan yihiin inay isticmaalaan hawo cufan si ay u nadiifiyaan dunta korantada, ka dibna si taxadar leh ugu wareeji xiriirka mid ka mid ah dhamaadka electrode iyo maroojin

Korodh-ku-dhejinta dhinaca kale. Isku dhaca duntu lama ogola.

5. Markaad garaacdo korantada, isticmaalayaashu waa inay isticmaalaan jillaab wareeg ah oo leh suuf taageero jilicsan xagga hoose ee ibta korantada si looga hortago dhaawaca dunta.

6.Ka hor inta aan la isku xirin elekrodes, isticmaalayaashu waa inay ku nadiifiyaan godka hawo cadaadis leh.

7.Isticmaal jillaab laastikada si aad kor ugu qaaddo korantada foornada, ka dibna hel xarunta oo si tartiib ah u dhaqaaji korantada.

8.Marka korantada sare hoos loo dhigo 20-30mm ka fog electrode hoose, dadka isticmaala waa in ay isticmaalaan hawo cadaadisay si ay u nadiifiyaan isgoyska ee electrode ah.

9.Isticmaal spanet torque gaar ah si aad u xoojiso korantada sida ku cad tilmaamaha, iyo isticmaal

makaanikada, Haydarooliga ee qalabka cadaadiska dabaysha si loo adkeeyo korantada si torque fifixed.

10. Haysta korantada waa in lagu xidhaa laba xariiq oo diirran oo cad

Inta u dhaxaysa xajiyaha iyo korantada waa inay nadiif ahaadaan si joogto ah si xiriir wanaagsan loo yeesho

electrode-ka, iyo biyaha qaboojiyaha ee haystaha waa in laga mamnuucaa inay soo daadan.

11. Dabool dusha sare ee korantada si aad uga fogaato oksidation iyo boodhka.

12.Si looga fogaado jebinta electrodes, isticmaalayaashu waa in aanay dhigin blocks dahaarka gudaha

foornada.Hadda shaqaynaysa ee electrode waa in ay la jaanqaadi kartaa shaqada la ogolyahay

hadda ku jira buug-gacmeedka.

13. Si aad uga fogaato jebinta korantada, dhig walxaha bulk qaybta hoose iyo qayb yar oo ka mid ah qaybta sare.

Quote Now

Quote Now