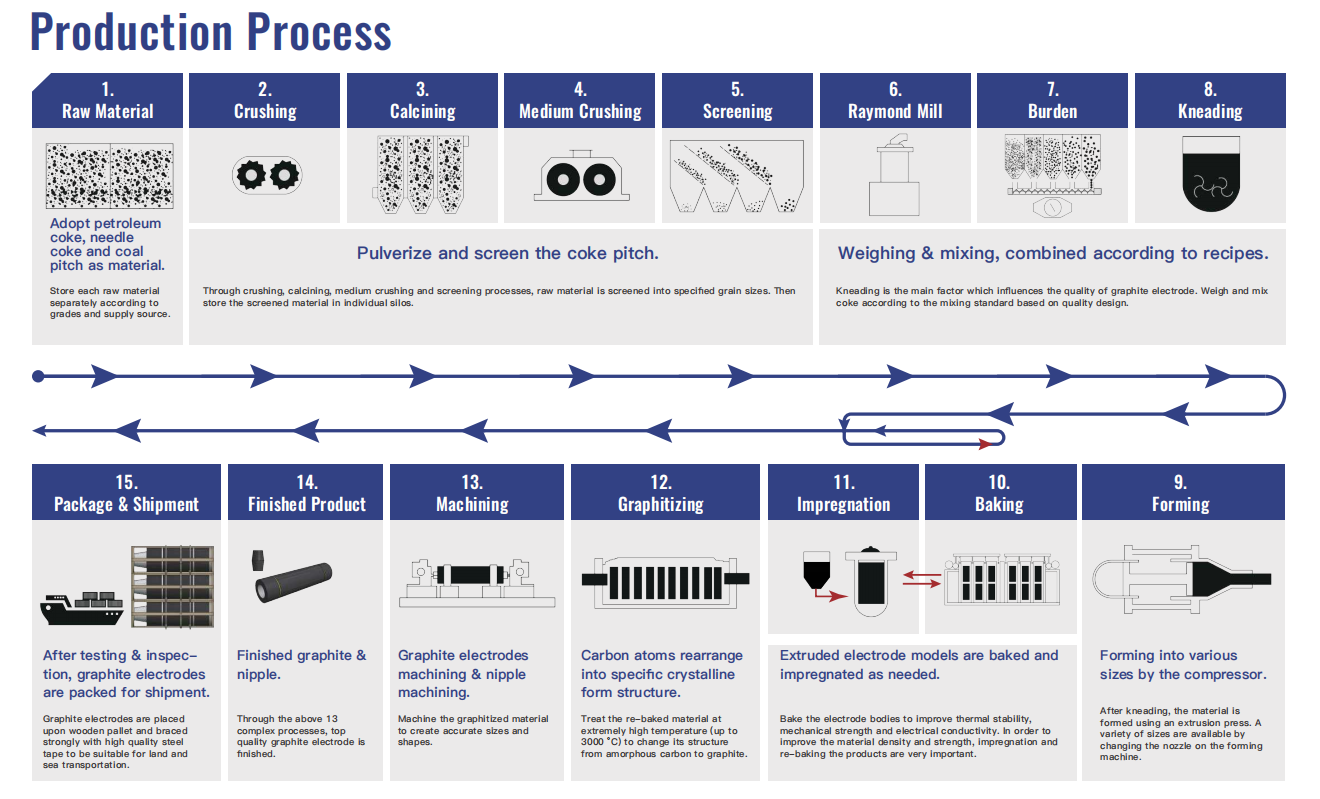

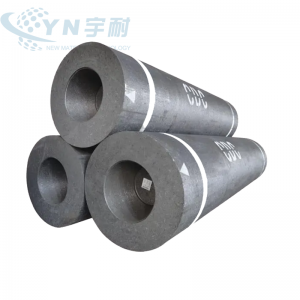

UHP Graphite Electrode oo leh ibta naaska

1. Hordhac :

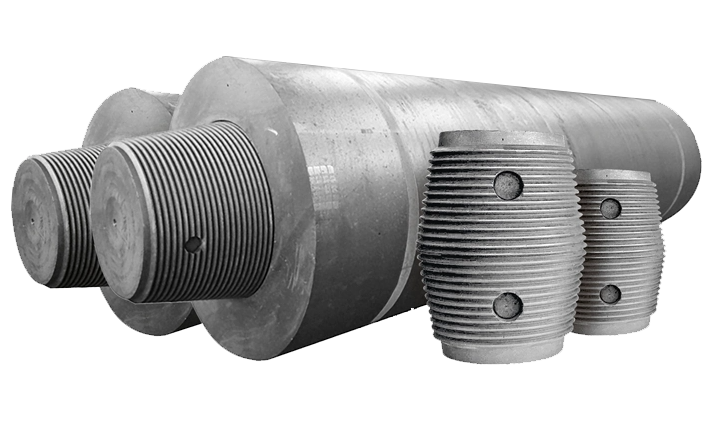

UHP graphite electrodewaxaa loo isticmaalaa dib-u-warshadaynta birta ee warshadaha foornooyinka korontada ku shaqeeya.Qaybteeda ugu muhiimsan waa coke irbad qiimaheedu sarreeyo, kaas oo ka samaysan batroolka ama daamurka dhuxusha.Electrode graphite waxa lagu farsameeyaa qaab cylindrical ah iyo meel duntu ka samaysan tahay ayaa lagu farsameeyaa cidhif kasta.Sidan, graphite electrode waxaa la isugu geyn karaa tiirka korantada iyadoo la isticmaalayo isku xirka korantada.

Si loo daboolo shuruudaha hufnaanta shaqada sare iyo qiimaha hoose ee hooseeya, awoodda weyn ee awoodda ultra-high ee foornada ayaa noqonaysa mid aad u caan ah.Sidaa darteed, electrodes graphite UHP oo leh dhexroor ka badan 500 mm ayaa xukumi doona suuqa

2. Astaamaha

- Caabbin sare oo hadda jira iyo heerka dheecaanka sarreeya.

- Degenaansho cabbir wanaagsan oo aan fududayn in la habeeyo.

- Iska caabinta dildilaaca iyo dhufashada.

- Iska caabbinta oksaydhaynta sare iyo iska caabinta shoogga kulaylka.

- Awood farsamo oo sarreeya iyo iska caabin hooseeya.

- Saxnaanta mashiinka sare iyo dhammayn dusha sare leh.

- Qaab dhismeedka lebbiska ah, hab-dhaqanka wanaagsan iyo kulaylka

3. Codsiga

Graphite electrode waxaa si weyn loo isticmaalaa inwax soo saarka birta daawaha, biraha iyo walxaha kale ee aan biraha ahayn.

foornada dabka ee DC.

foornada AC.

Foornada arc ee hooseysa.

foornada ladle.

(1) Koronto graphite awood joogto ah

Waxaa loo ogol yahay in la isticmaalo graphite electrode leh cufnaanta hadda ka hooseeya 17a / cm2, taas oo inta badan loo isticmaalo foornooyinka korontada caadiga ah ee birta, dhalada silikon, dhalada fosfooraska jaalaha ah, iwm.

(2) Electrode graphite ee dahaarka leh oksidation-ka

Electrode graphite oo lagu dahaadhay lakabka difaaca ee antioxidant (graphite electrode antioxidant).Samee lakab ilaalin ah oo qaban kara koronto oo iska caabin kara oksaydhka heerkulka sare, hoos u dhigida isticmaalka korantada inta lagu jiro samaynta birta (19% ~ 50%), sii kordhiso nolosha adeegga elektiroonigga (22% ~ 60%), oo hoos u dhigta isticmaalka tamarta korantada ee electrode ah.Caannimada iyo isticmaalka tignoolajiyadaani waxay keeni kartaa saamayn dhaqaale iyo bulsho:

① Cunista halbeegga korantada graphite waa ka yar tahay, qiimaha wax soo saarkana waa la dhimay ilaa xad.Tusaale ahaan, warshad samaynta birta, oo ku salaysan isticmaalka 35pcs graphite electrodes todobaadkii iyo 165 foornooyinka sifaynta ee foornada nadiifinta aasaasiga ah ee LF iyada oo aan la xidhin sanadka oo dhan, 373pcs graphite electrodes waa la badbaadin karaa sanad kasta ka dib markii tignoolajiyada iska caabinta graphite electrode ay tahay korsaday

(153 tan) electrode, oo lagu xisaabiyo 3000USD tan oo koronto aad u sareysa sanadkii, USD 459,000 waa la badbaadin karaa.

② Electrode graphite wuxuu isticmaalaa awood yar, wuxuu badbaadiyaa isticmaalka tamarta birta samaynta cutubka, wuxuu badbaadiyaa qiimaha wax soo saarka wuxuuna kaydiyaa tamarta!

③ Sababtoo ah graphite electrode waa la beddelaa waqtiyo ka yar, tirada shaqada iyo khatarta isku dhafka hawlwadeenada waa la dhimay, waxtarka wax soo saarkana waa la hagaajiyay.

④ Electrode graphite waa isticmaalka hooseeya iyo badeecada wasakhaysan ee hooseeya.Maanta, marka ilaalinta tamarta, dhimista qiiqa iyo ilaalinta deegaanka ayaa loo ololeeyaa, waxay leedahay muhiimad bulsho oo muhiim ah.

Farsamadan ayaa weli ku jirta heerka cilmi baarista iyo horumarinta Shiinaha, qaar ka mid ah soosaarayaasha gudaha ayaa sidoo kale bilaabay inay soo saaraan.Waxaa si weyn looga isticmaali jiray Japan iyo dalalka kale ee horumaray.Waqtigan xaadirka ah, waxaa sidoo kale jira shirkado ku takhasusay soo dejinta daahan ka hortagga oksaydhka ee Shiinaha.

(3) Koronto garaafyada awoodda sare leh.Electrode graphite leh cufnaanta hadda ee 18 ~ 25A / cm2 waa la oggol yahay in la isticmaalo, taas oo inta badan loo isticmaalo foornada koronto ee awoodda sare leh ee samaynta birta.

(4)Electrode graphite awood sare leh.Electrodes Graphite UHP cufnaanta hadda ka weyn 25A/cm2 waa la ogol yahay.Waxaa inta badan loo isticmaalaa foornada qaansada korontada ee birta ah ee awoodda aadka u sareysa.

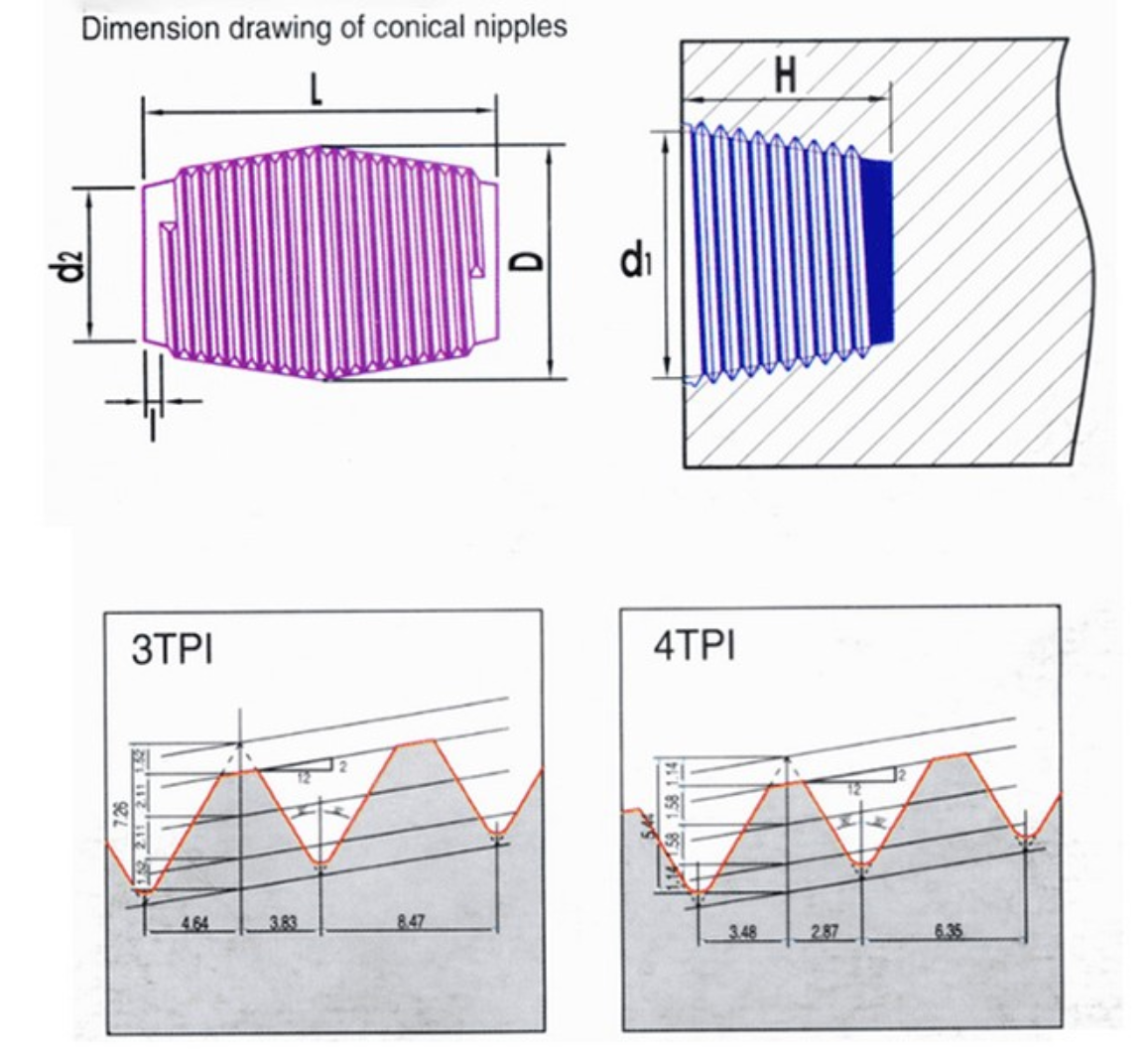

4. Ibta naaska

3TPI/T4L/T4N Ama la habeeyay

5. Qiyaasta Alaabta

Graphite ElectrodeFaahfaahin dheeraad ah iyo Faahfaahin:

Si aad u raacdo kaliya tixraacaada:

| Walxaha | Awoodda joogtada ah (RP) | Awood sare (HP) | Awood aadka u sarreeya (UHP) | |||||||

| 200-300 | 350-600 | 700 | 200-400 | ⌽450-600 | 700 | ⌽250-400 | ⌽450-600 | 700 | ||

| ResistanceμΩm (Max) | Electrode | 7.5 | 8.0 | 6.5 | 7.0 | 5.5 | 5.5 | |||

| Ibta naaska | 6.0 | 6.5 | 5.0 | 5.5 | 3.8 | 3.6 | ||||

| BulkDensityg/cm3 (min) | Electrode | 1.53 | 1.52 | 1.53 | 1.62 | 1.60 | 1.62 | 1.67 | 1.66 | 1.66 |

| Ibta naaska | 1.69 | 1.68 | 1.73 | 1.72 | 1.75 | 1.78 | ||||

| BendingStrengthMpa (Min) | Electrode | 8.5 | 7.0 | 6.5 | 10.5 | 9.8 | 10.0 | 11.0 | 11.0 | |

| Ibta naaska | 15.0 | 15.0 | 16.0 | 16.0 | 20.0 | 20.0 | ||||

| Young'ssmodulusGpa (Max) | Electrode | 9.3 | 9.0 | 12.0 | 12.0 | 14.0 | 14.0 | |||

| Ibta naaska | 14.0 | 14.0 | 16.0 | 16.0 | 18.0 | 22.0 | ||||

| Ash% (Max) | Electrode | 0.5 | 0.5 | 0.3 | 0.3 | 0.3 | 0.3 | |||

| Ibta naaska | 0.5 | 0.5 | 0.3 | 0.3 | 0.3 | 0.3 | ||||

| CTE(100-600℃)×10-6/℃ | Electrode | 2.9 | 2.9 | 2.4 | 2.4 | 1.5 | 1.4 | |||

| Ibta naaska | 2.8 | 2.8 | 2.2 | 2.2 | 1.4 | 1.2 | ||||

Qiyaasta caadiga ah ee Electrode: Haddii ay jiraan shuruudo gaar ah, labada dhinacba waxay la tashadaan sahayda & baahida.

Si aad u hesho cabbirro faahfaahsan oo dheeraad ah:Uhp Graphite electrode , Graphite Electrode , Hp Graphite Electrode , Rp Graphite Electrode φ200mm-700mm Dhererka 1800mm -2700mm

| Cabbirrada caadiga ah ee korantada | ||||||

| Tilmaamaha (inch) | Dhexroorka La Ogolyahay (mm) | Dhererka La Oggolyahay (mm) | ||||

| Dhexroor Magaca | Max. | Min. | Dhererka magacaaban | Max. | Min. | |

| 6 | 150 | 154 | 151 | 1600 | 1700 | 1500 |

| 1800 | 1875kii | 1700 | ||||

| 8 | 200 | 205 | 200 | 1600 | 1700 | 1500 |

| 1800 | 1875kii | 1700 | ||||

| 9 | 225 | 230 | 225 | 1600 | 1700 | 1500 |

| 1800 | 1875kii | 1700 | ||||

| 10 | 250 | 256 | 251 | 1600 | 1700 | 1500 |

| 1800 | 1875kii | 1700 | ||||

| 12 | 300 | 307 | 302 | 1800 | 1875kii | 1700 |

| 14 | 350 | 357 | 352 | 1600 | 1700 | 1500 |

| 1800 | 1875kii | 1700 | ||||

| 16 | 400 | 409 | 403 | 1600 | 1500 | 1500 |

| 1800 | 1875kii | 1700 | ||||

| 2100 | 2175 | 1975kii | ||||

| 18 | 450 | 460 | 454 | 1800 | 1875kii | 1700 |

| 2100 | 2175 | 1975kii | ||||

| 2400 | 2475 | 2275 | ||||

| 20 | 500 | 511 | 505 | 1800 | 1875kii | 1700 |

| 2100 | 2175 | 1975kii | ||||

| 2400 | 2475 | 2275 | ||||

| 22 | 550 | 562 | 556 | 2100 | 2175 | 1975kii |

| 2400 | 2475 | 2275 | ||||

| 24 | 600 | 613 | 607 | 2100 | 2175 | 1975kii |

| 2400 | 2475 | 2275 | ||||

| 2800 | 2850 | 2550 | ||||

| 28 | 700 | 714 | 708 | 2400 | 2475 | 2275 |

| 2800 | 2850 | 2550 | ||||

Awood Qaadashada Hadda ee Graphite Electrode:

| Dhexroor magaca ah (mm) | Awoodda Joogtada ah | Awood sare | Ulra High Power | |||

| Culayska Hadda (A) | Cufnaanta Hadda (A/cm2) | Culayska Hadda (A) | Cufnaanta Hadda (A/cm2) | Culayska Hadda (A) | Cufnaanta Hadda (A/cm2) | |

| 200 | 5000-6900 | 15-21 | 5500-9000 | 18-25 | ———— | ———— |

| 225 | 6100-8600 | 15-21 | 6500-10000 | 18-25 | ———— | ———— |

| 250 | 7000 ilaa 10000 | 14-20 | 8000 ilaa 13000 | 18-25 | ———— | ———— |

| 300 | 10000 ilaa 13000 | 14-18 | 13000 ilaa 17400 | 17-24 | 15000 ilaa 22000 | 20-30 |

| 350 | 13500 ilaa 18000 | 14-18 | 17400 ilaa 24000 | 17-24 | 20000 ilaa 30000 | 20-30 |

| 400 | 18000 ilaa 23500 | 14-18 | 21000 ilaa 31000 | 16-24 | 25000 ilaa 40000 | 19-30 |

| 450 | 22000 ilaa 27000 | 13-17 | 25000 ilaa 40000 | 15-24 | 32000 ilaa 45000 | 19-27 |

| 500 | 25000 ilaa 32000 | 13-16 | 30000 ilaa 48000 | 15-24 | 38000 ilaa 55000 | 18-27 |

| 550 | 32000 ilaa 40000 | 13-16 | 37000 ilaa 57000 | 15-23 | 42000 ilaa 66000 | 17-26 |

| 600 | 38000 ilaa 47000 | 13-16 | 44000 ilaa 67000 | 15-23 | 49000 ilaa 88000 | 17-26 |

| 700 | 48000 ilaa 59000 | 12-15 | 59620-83600 | 13-18 | 70000-110000 | 17-24 |

Quote Now

Quote Now